VIRTUAL OFFICE

Company

Accessibility

The Company is a virtual engineering and design consulting firm that specializes in Product Design and development, mold design, and analysis. We have over 30 plus years of working in various capacities in both management, engineering, and manufacturing. We have other expert associates in industrial design, electrical engineering, circuit board development, analysis, plastics processing, and training. These skills and relationships are a critical addition to our capabilities and allow us to work virtually in many industries anywhere in the world. We typically work electronically with video teleconferences, web based file transfer, and email but we are also capable of bringing our computers to our customer’s facilities to work on, discuss, or review projects.

Our team is committed to helping our customers solve new and existing problems by applying our wide range of education, skills, experience, and computer simulation software to deliver a world class solution. We can either help your existing engineering department or be your entire external engineering solution. Many of our customers do not have a complete engineering department and find it extremely efficient to only call us when their projects require help. We normally can respond faster and also with more experience and end up as a less expensive option in the long run.

Company

Versatility

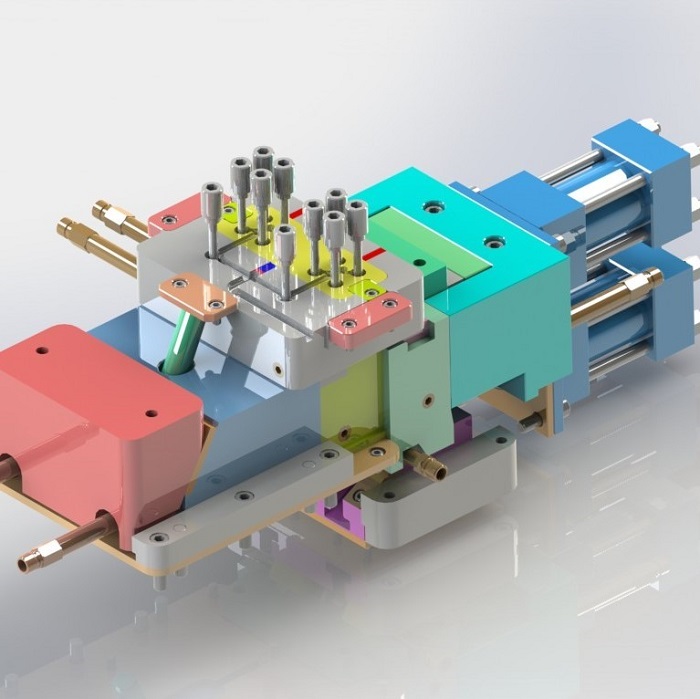

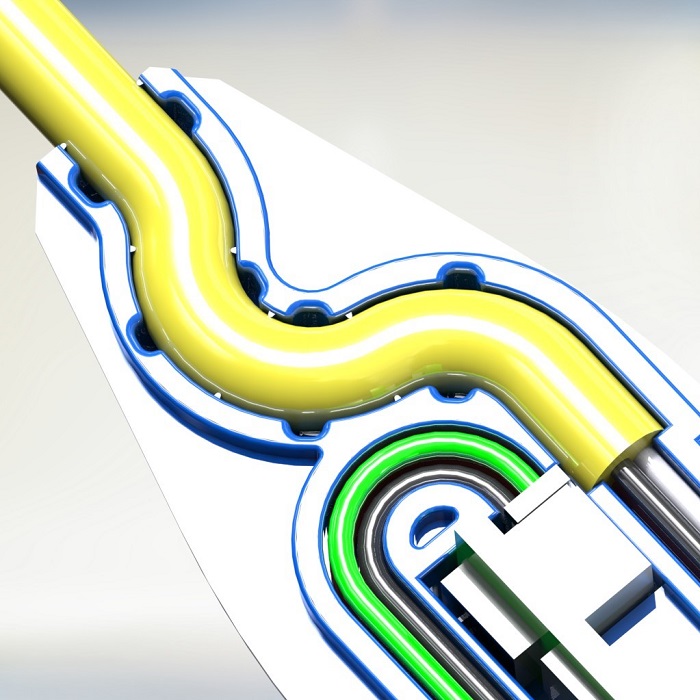

We are a small yet nimble virtual engineering company that specializes in product design, computer simulation, and mold design. We strategically combine several experts across multiple engineering and manufacturing disciplines to optimize our customer’s projects. We focus on Product Design, Stress Analysis, Mold Design, Mold Filling Analysis, and Process Optimization. By working across the design and manufacturing process allows us to manage the engineering data that gets transferred from each discipline to the next. Our goal is actually quite simple. We want to help improve the communications of product data while optimizing the process along the way. There are many strategies out there that companies try to employ like the STAGE GATE PROCESS, or LEAN, or Six Sigma to address the decision making process, cost reduction strategies, and improving quality standards. While this may help humans review, plan, and improve the communication process, it does not really address the design data. We directly address the product design intent and associated analysis and test data to predict problems and fix them early in the design phase.

Our Goals

Procad Technologies has very simple goals. We want to help our customers create a world class product by creating a new or existing product into a world class designs and state of the art manufacturing processes that are of higher quality, longer durability, and improved profitability.

- To develop new products or optimize existing products by reviewing best practices material selection, product shape, and design requirements.

- Review that product design for critical characteristics and use computer simulation as required to analyze the product strength, material stress, and thermal conditions for final product function. This includes both plastic and metal components.

- Review the product design for tooling for issues such as draft, parting lines, and mold function.

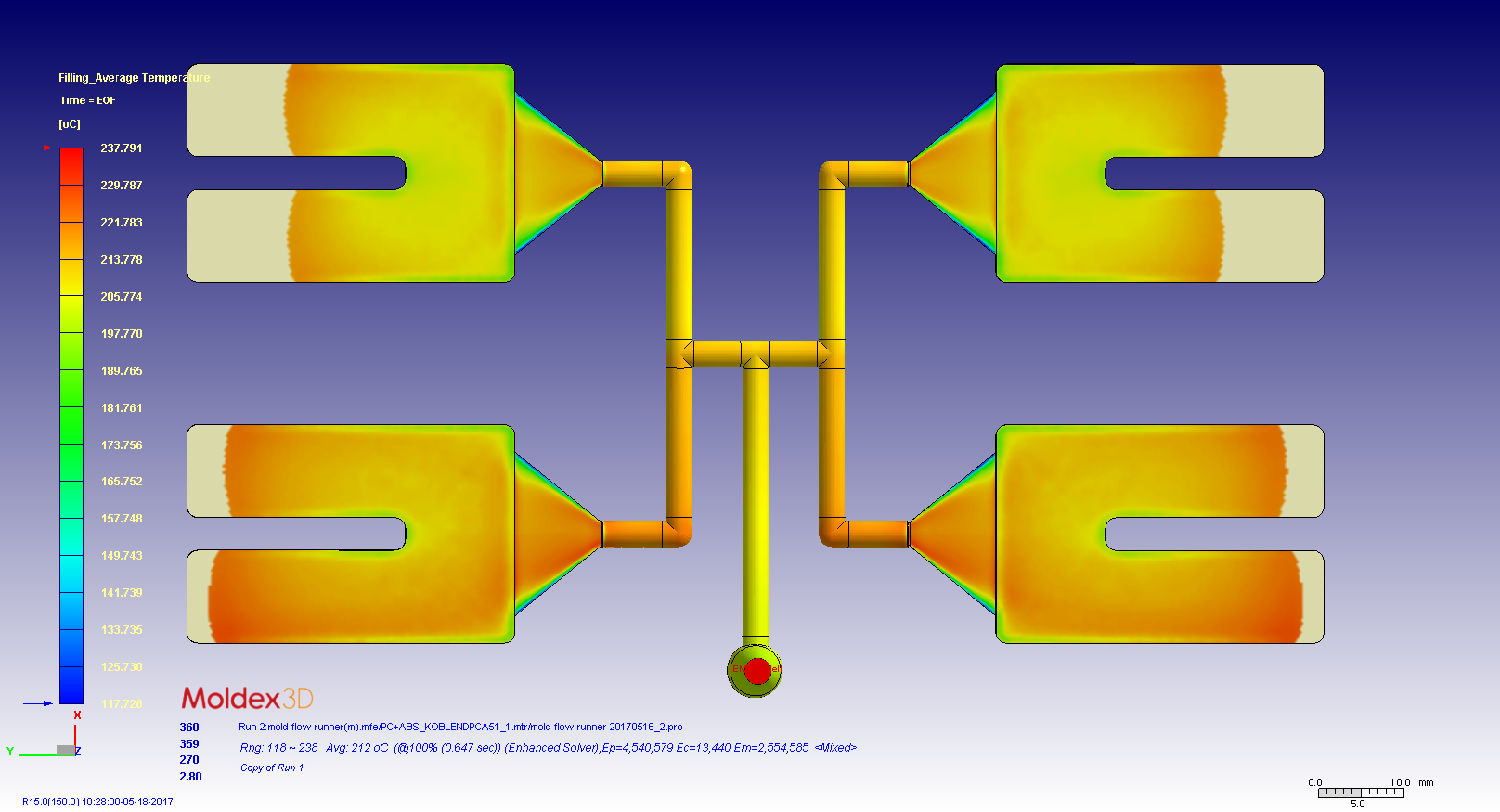

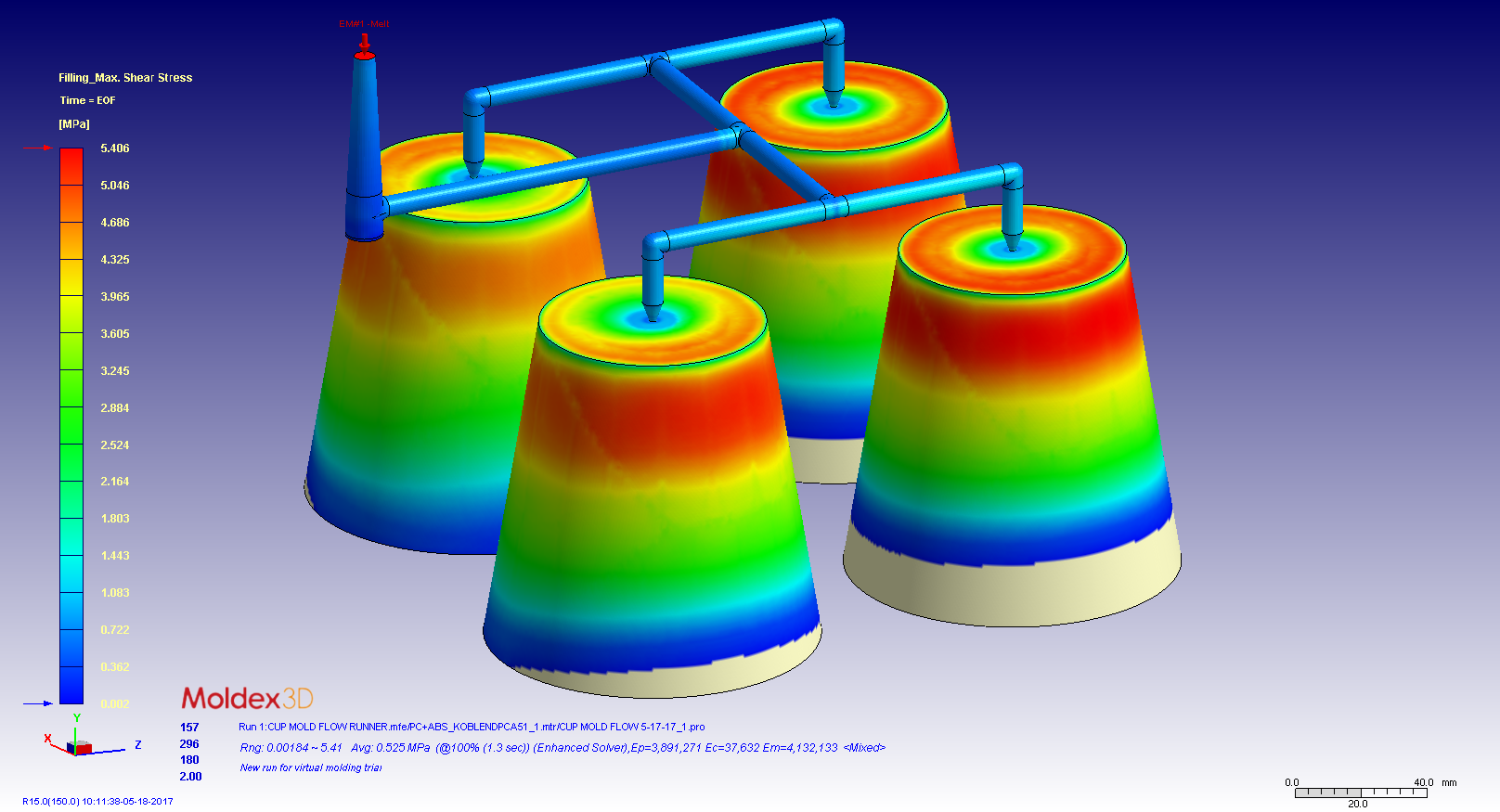

- Review the product design and tooling plan for gate locations, runner design, and overall mold performance including water lines for cooling.

- Perform a complete mold filling analysis to verify flow patterns, temperatures, molded in stresses, melt temperatures.

- Perform packing, cooling, and warpage analysis to verify parts are molded to tolerance.

- Review analysis results and make product, material, and process changes to ensure proper product performance, and the profit plan

We help our customers from concept clear through to product supporting all aspects of the engineering data, product prototyping, product performance, and product testing. Give us a call on your next project so we can help you optimize your process.

If you have a Vision We will help you to turn it into reality

Optimize Your Process

These experiences have lead to the realization that American companies that design and manufacturing need more help to be more competitive with offshore companies. There are many inefficient products that are designed in the inefficient materials, thick wall thickness, and poor processing conditions that waste as much as 50% on cycle time. Not only are the designs flawed, the cycle time and profitable are terrible; but we also find that the material properties were dramatically degraded because of improper gate location, size, runner design, inherent flow patterns and press processing parameters.

Computer Simulation

It is for these reasons that we focus on helping our customers to better design the products upfront and then virtually optimize them for manufacturing. If we are going to compete in a global economy, we must adjust to different cost structures, quality requirements, shipping time, and associated costs. In most cases, our customers only have one chance to design and build a product and that making that world class on time is a huge challenge. Our wide range of computer simulation includes stress analysis, thermal analysis, impact analysis, dynamic analysis, and especially mold filling analysis. When you combine 2 or more of these analysis together, the results can be quite amazing and project profit can go up dramatically. We typically see an improvement of 10% to 50% on every project we touch depending on customer requirements and available schedule.

In order to help accomplish this, we take our small and agile company, its associates, and work directly with other companies both large and small. We can be a small companies complete virtual company or a larger companies engineering support on projects that are either too hard or too difficult to finish on time. We have been asked to get involved in other international projects that were either seriously flawed, breaking, or inefficient and required expensive analysis and optimization. It is based on this optimization that has allowed us to break into some very critical companies in automotive, medical, and industrial markets.

Meet our team and associates

Learn more about why our company was created and how we got here.

Read more about our goals

Our Team

Procad Tchnologies, LLC

ALL RIGHTS RESERVED

Contact

352-600-7473

Spring Hill, FL