MATERIAL SELECTION

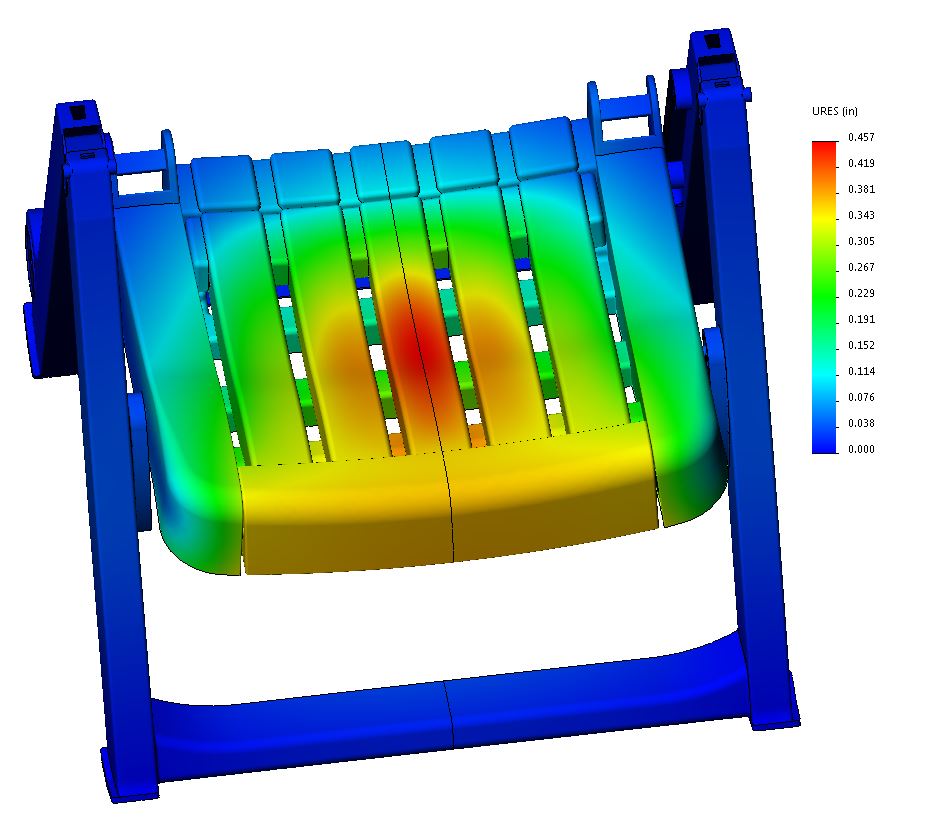

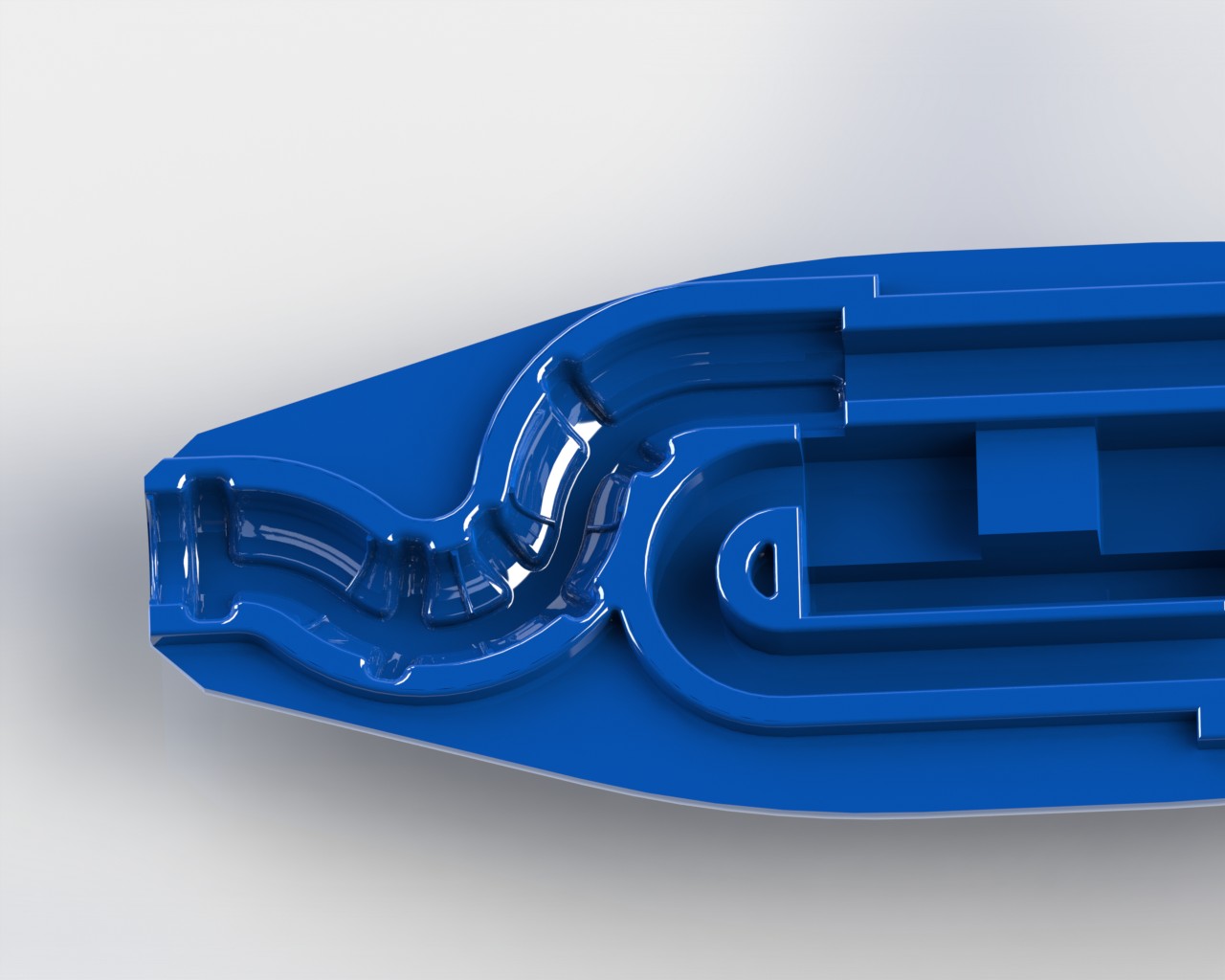

Product design has many increasingly difficult challenges. Designs must be beautiful, strong, durable, easy to produce, and inexpensive to produce. Product requirements are becoming more difficult to pass and when it comes to plastics, the may be difficult to process. While new materials are developed all the time, their processing becomes more difficult to achieve things such as high tensile strength, high impact resistance, or long flow length capabilities. So the product material selection becomes so critical that it literally can make or break the entire project if not done correctly. Unlike metals, plastics are non-linear in behavior or in other words, their strength is not consistent as they stretch or bend. Steels and aluminum behave more linear and are much easier to predict during design. Specialized software packages such as Mold Filling Analysis can be used to monitor the plastic flow of the material and Stress Analysis and Impact Analysis can be performed to ensure that material performs as expected once molded.

Procad Tchnologies, LLC

ALL RIGHTS RESERVED

Contact

352-600-7473

Spring Hill, FL