MOLD FILLING ANALYSIS

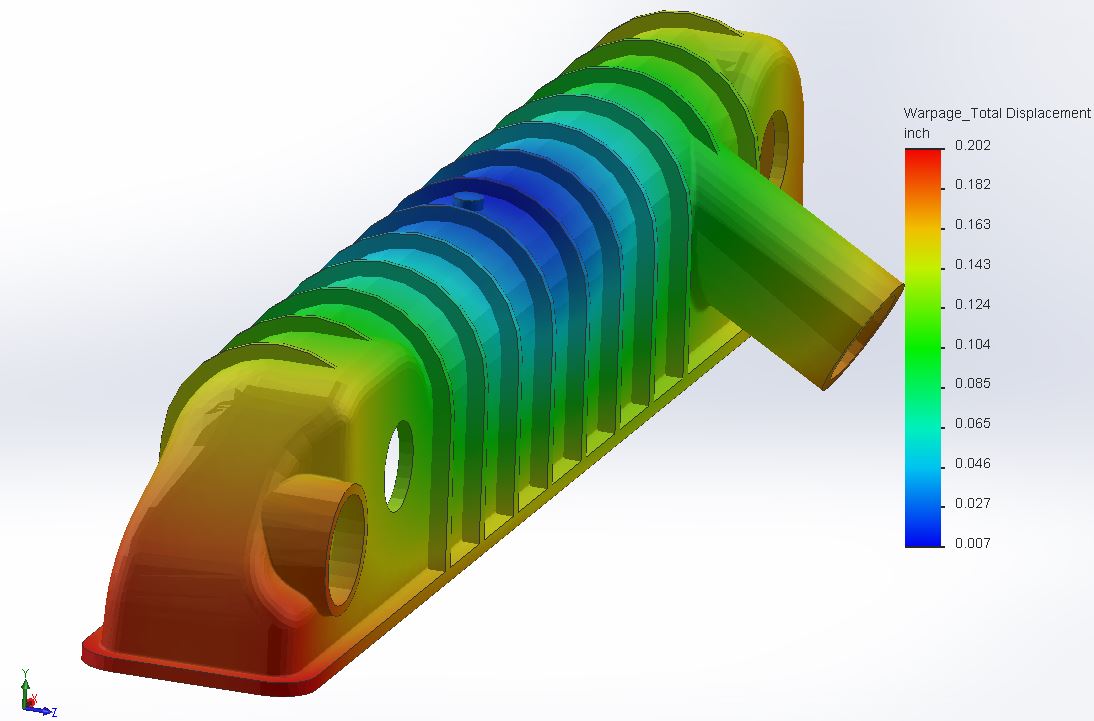

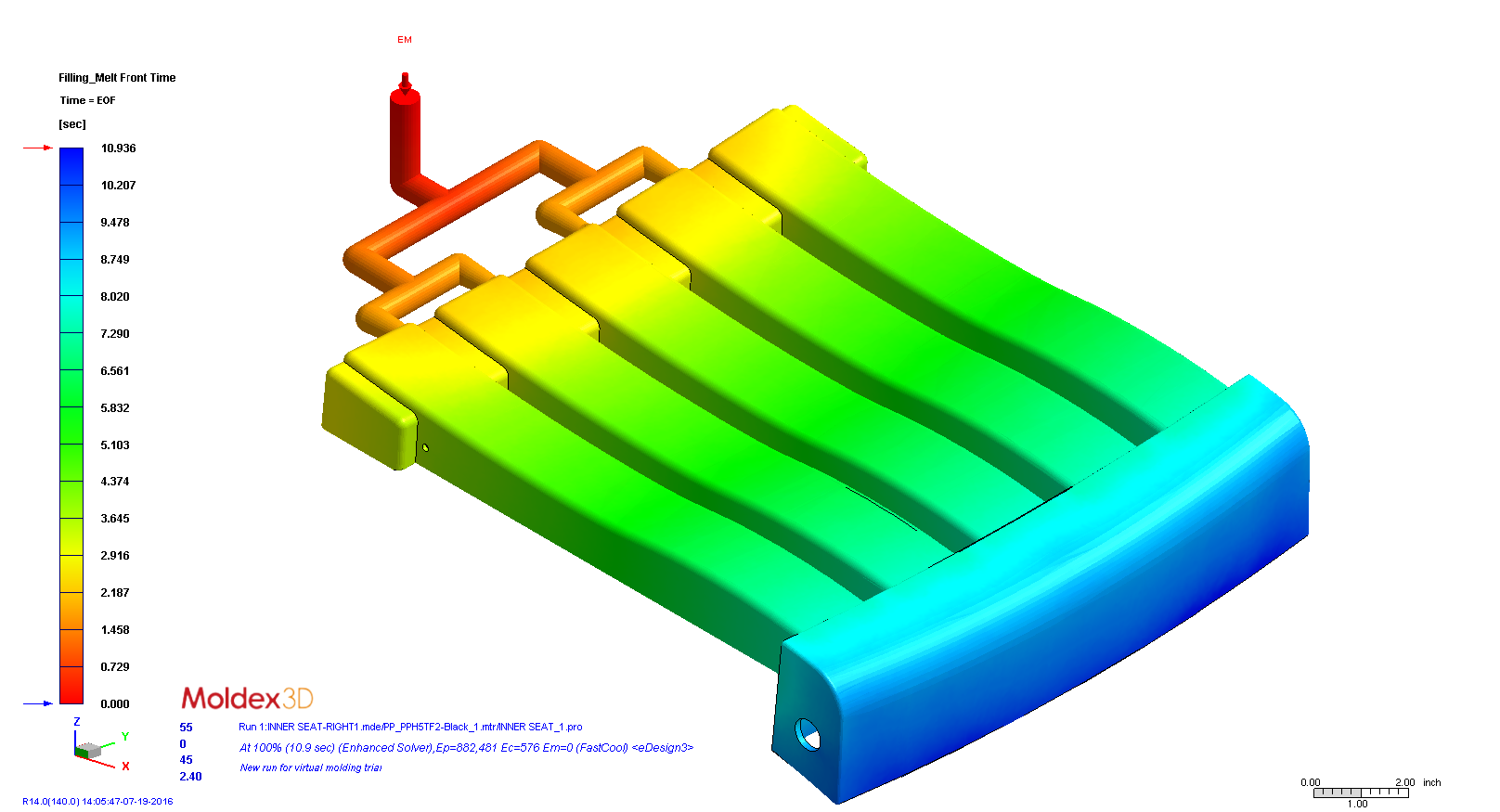

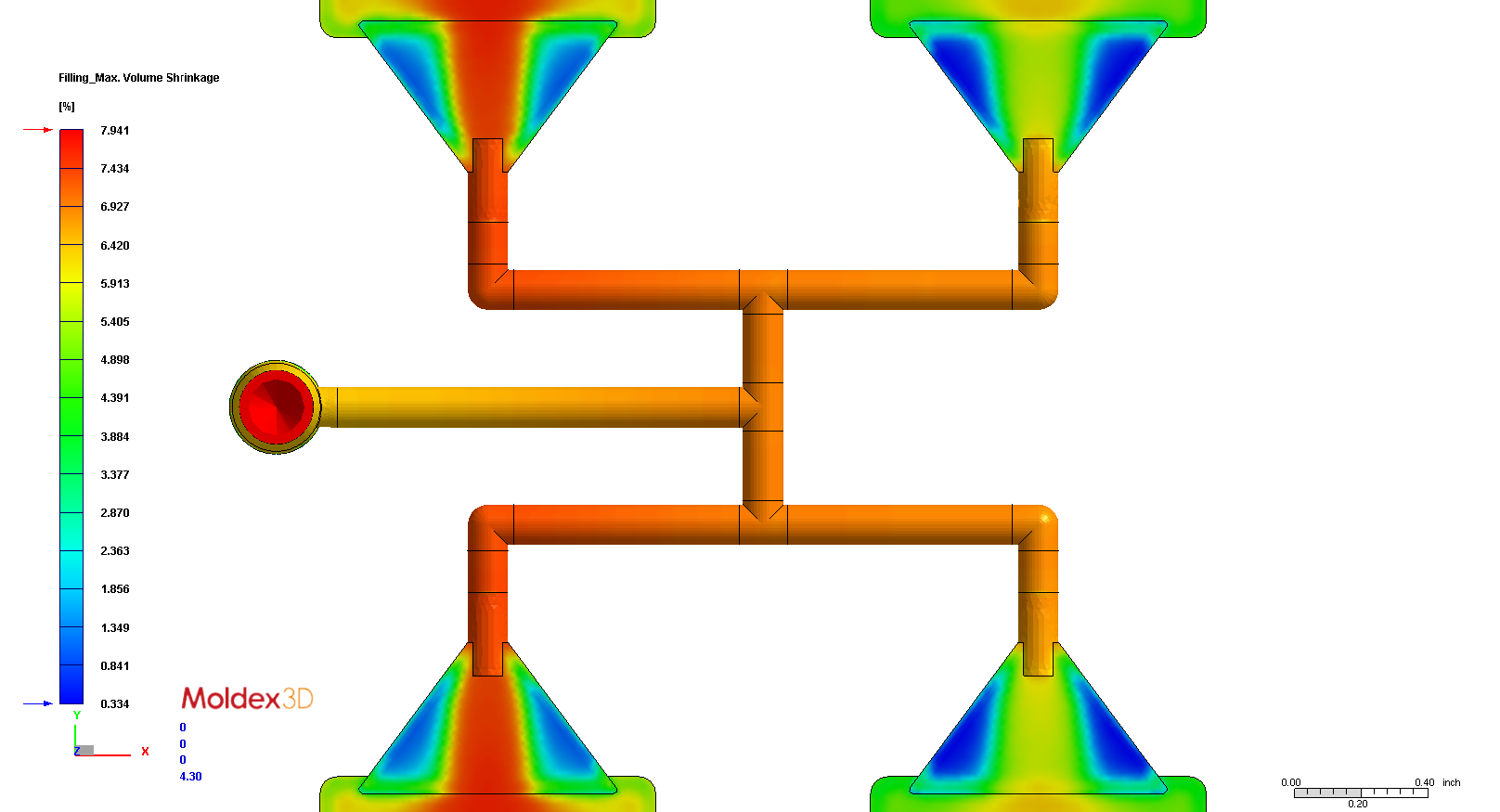

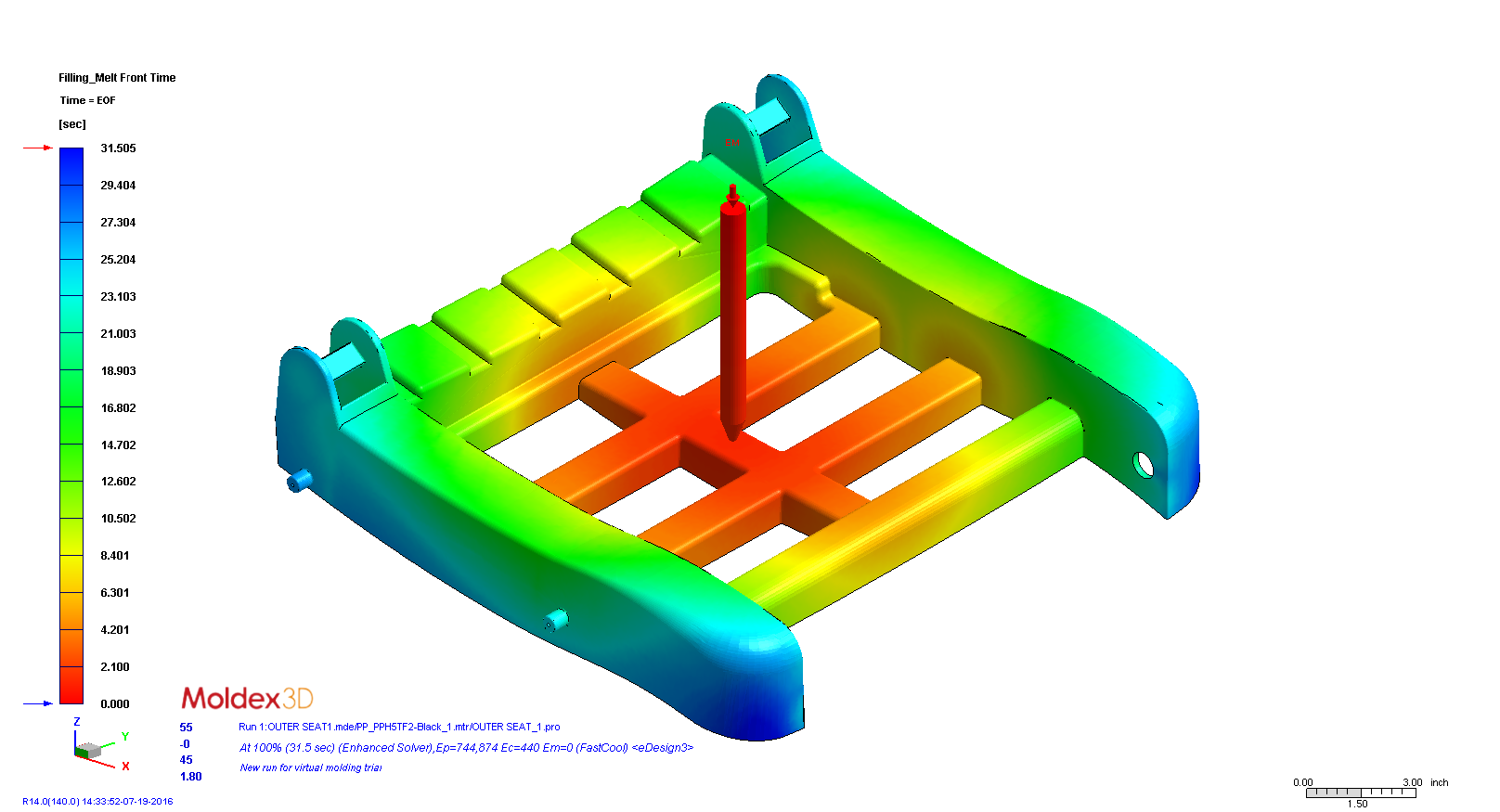

Our innovative and professional team specializes in the optimization of your project. We often utilize Mold Filling Analysis to improve upon design and ultimately increase revenue. From trouble shooting existing production to creating an efficient new product and preventing mistakes and waste, our virtual office is at your service. We employ professionals with years of experience in a combination of specialties. This system allows us to analysis all aspects of design and product to create the best possible quality, often at a fraction of the cost. We can manage complex mold filling patterns and material characteristics with the aid of our analysis. While this may not seem that important, lack of tooling experience can substantially increase product design problems by increasing tooling costs. This can create difficult mold filling problems and also by making extra moving mechanisms and molding conditions that are nearly impossible to process. Our mold filling analysis is very critical to the process improvement and Cycle Time Reduction.

The software analyzes fill time, pressure, shear rate, cooling time, weld lines, air traps, voids, and sinks. We have been asked to fix or improve many parts to help improve these conditions by reducing the cycle time or scrap rate caused by thick walls and bad mold filling conditions. We have found that by focusing on analysis and molding best practices, we have been able to improve critical process issues by 10% to 50% consistently. When these savings are combined with molding machines and secondary equipment, it is possible to see savings over $100,000 per year. We look at the entire process and weigh compromises between what the product needs, the material sweet spot, and the manufacturing complexities. They all must align in order for the final product to work correctly and be durable.

Procad Tchnologies, LLC

ALL RIGHTS RESERVED

Contact

352-600-7473

Spring Hill, FL