MOLD DESIGN

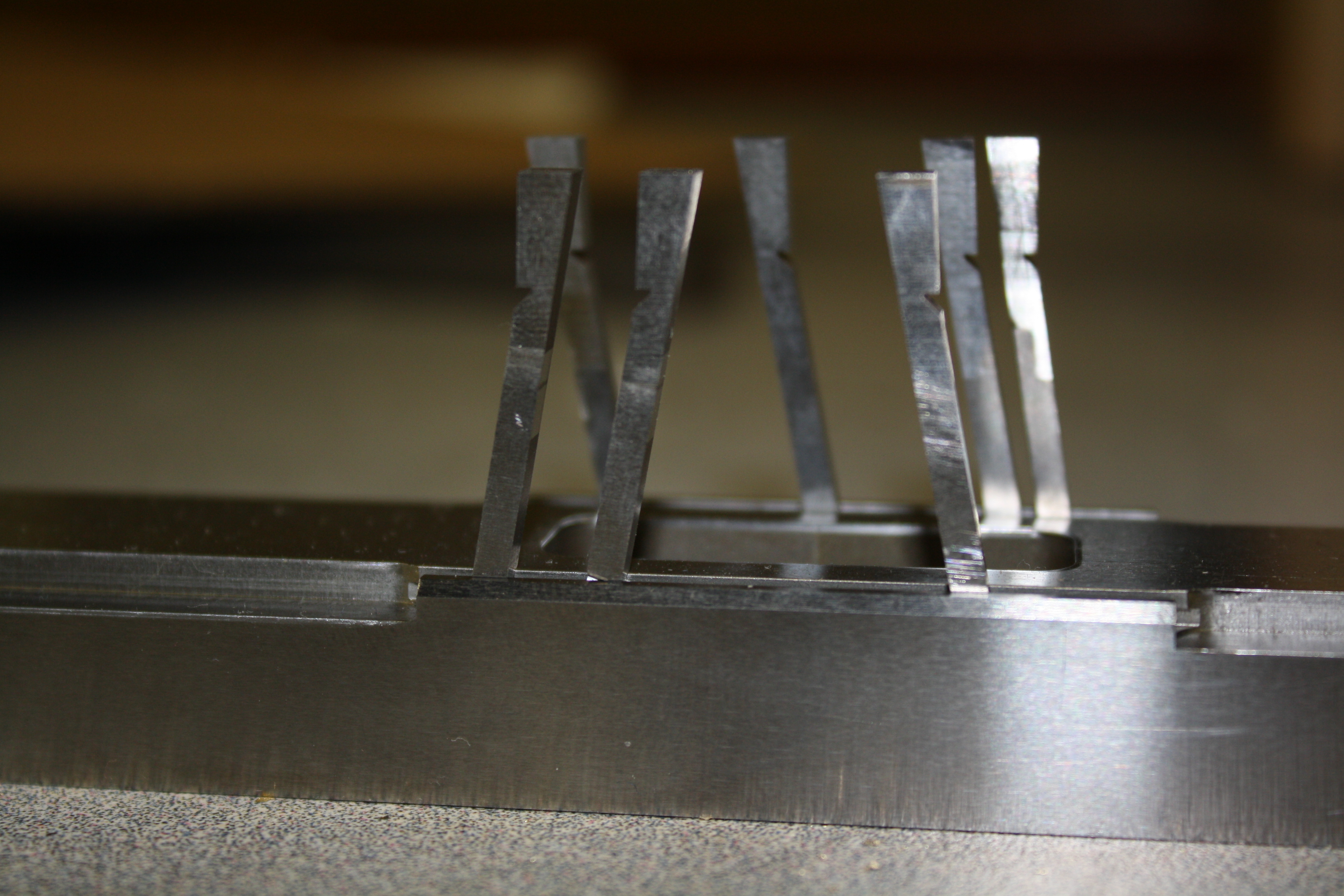

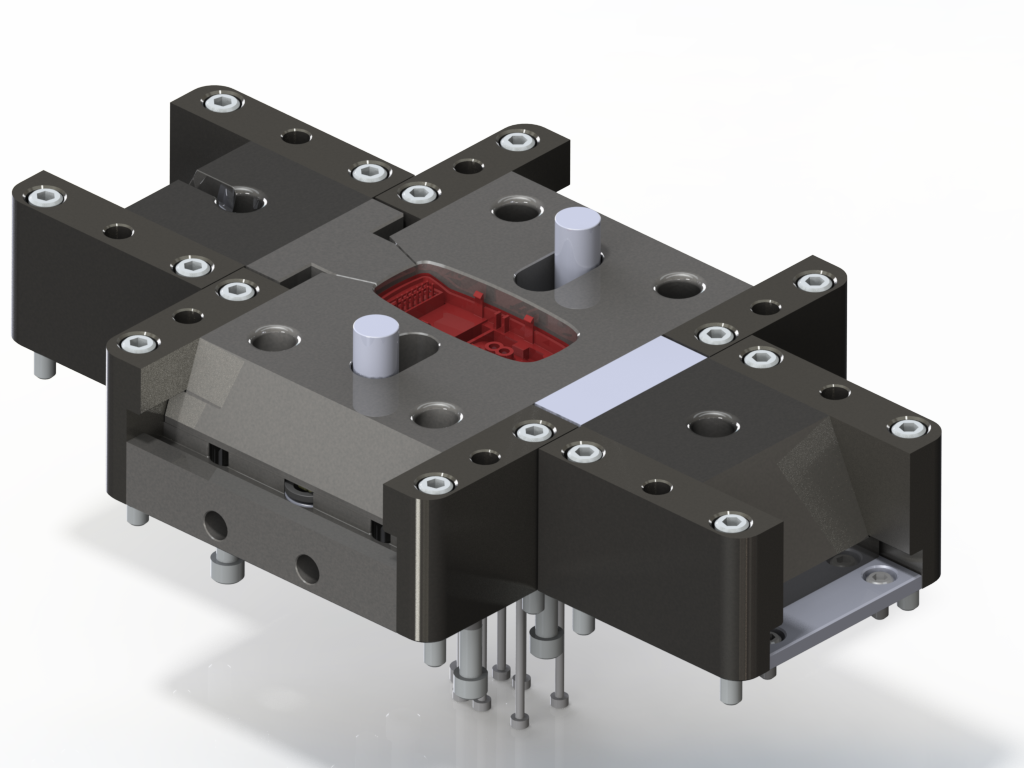

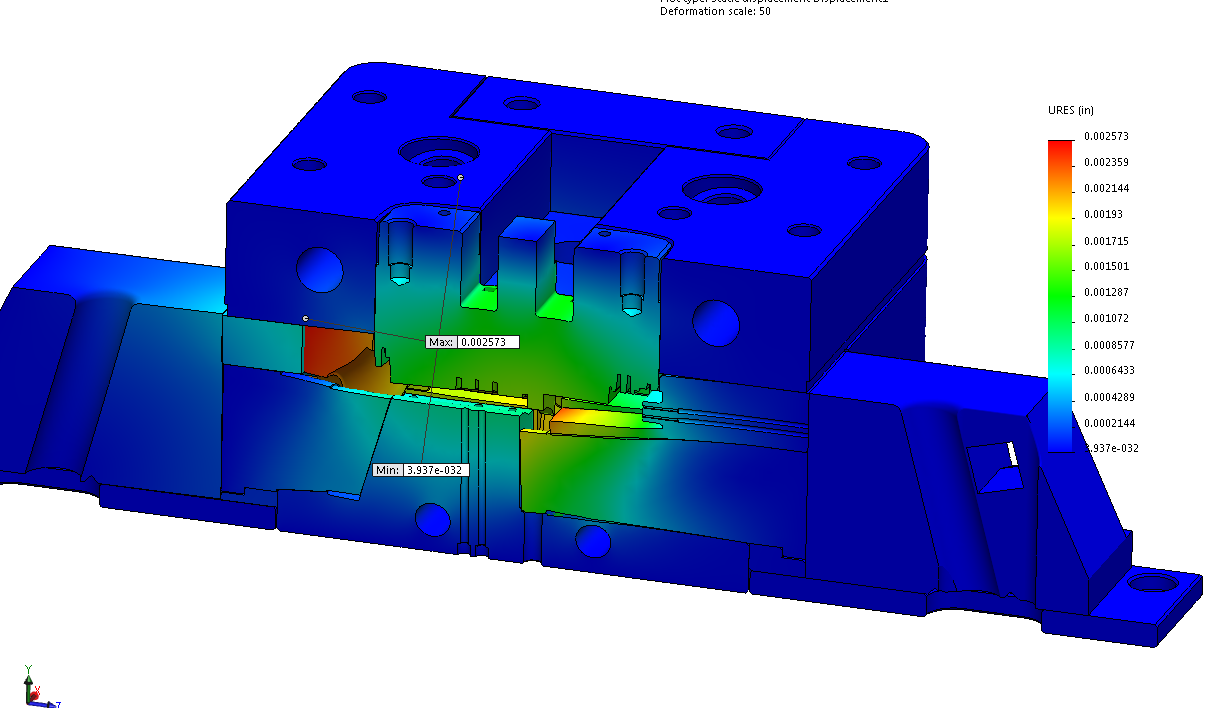

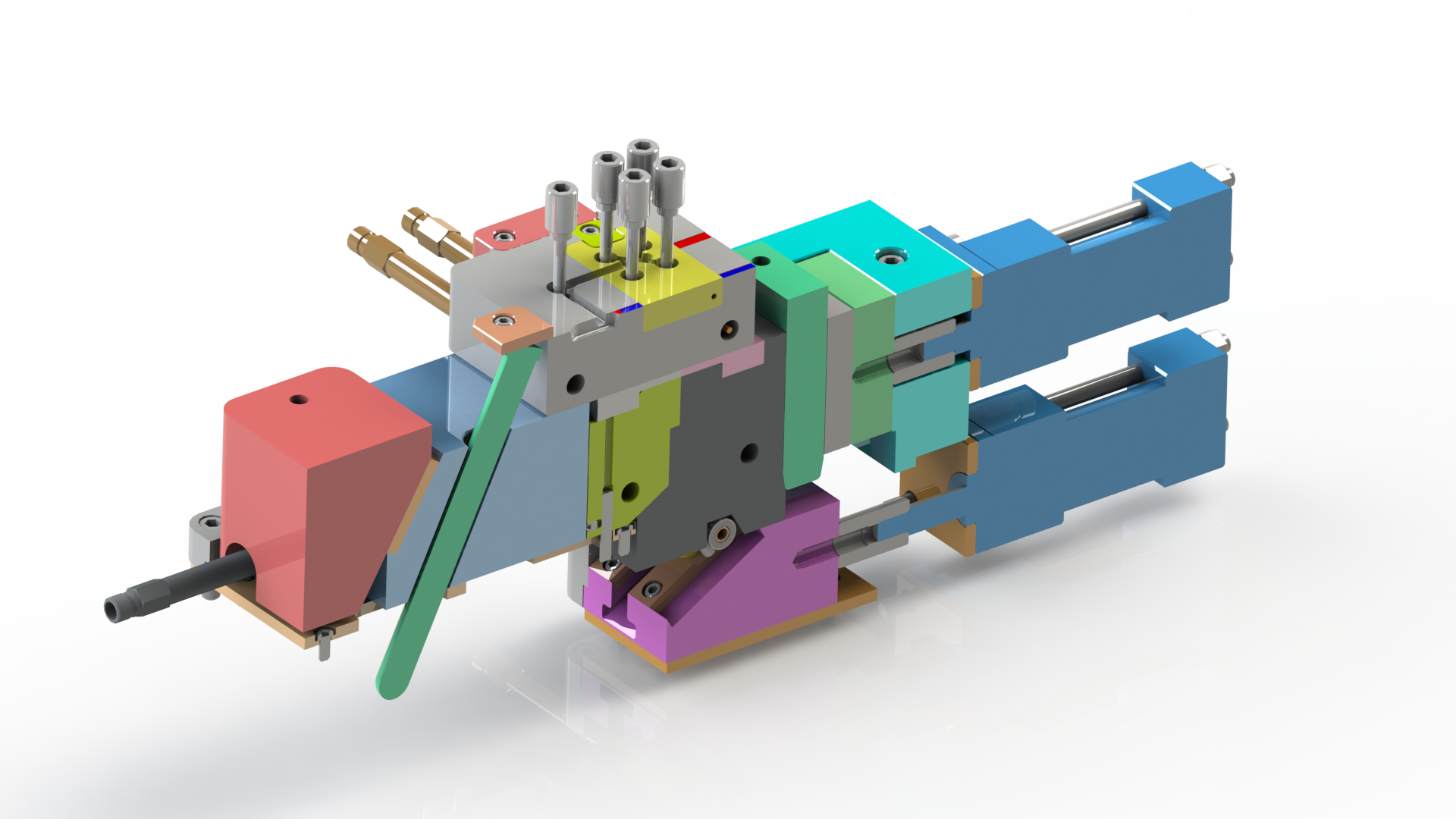

Procad Technologies offers a complete set of mold design and tool engineering solutions to our customers. To us, mold design is much more than just designing a cavity and core set in a mold base that happens to match your desired part shape. Our experience has taught us that the unique properties of plastics combined with variations in materials and processing can make for many complex tooling and molding, problems. We review the molds for more than just inserts and tight tolerances. Mold filling requirements and runner balancing are considered. The strength of steel is evaluated for steel deflections that may lead to flash or even mold breakage. Understanding the molding process, the molding press, and molding process can generate tool flex, twist, and crush. We bring true engineering to tool design. We have the tools, software, and experiences to review tools far beyond other design firms and tool shops.

We have software that analyze the molding filling process and establish filling times, cooling times, material shrinkage, flow direction, and molded in stress. These details are critical to evaluate the performance of not only the mold but also the material within that mold. Materials that degrade easily may exceed their processing limits based on thin wall sections, small gate sizes, wrong gate locations, and poor processing conditions. We can also take the pressure calculations and determine whether the mold is going to blow open or even bend and break under the extreme pressures or the non-uniform flow front created by the part geometry and gate location.

Give us a call so that we can help you optimize your next project.

Procad Tchnologies, LLC

ALL RIGHTS RESERVED

Contact

352-600-7473

Spring Hill, FL