STRESS ANALYSIS

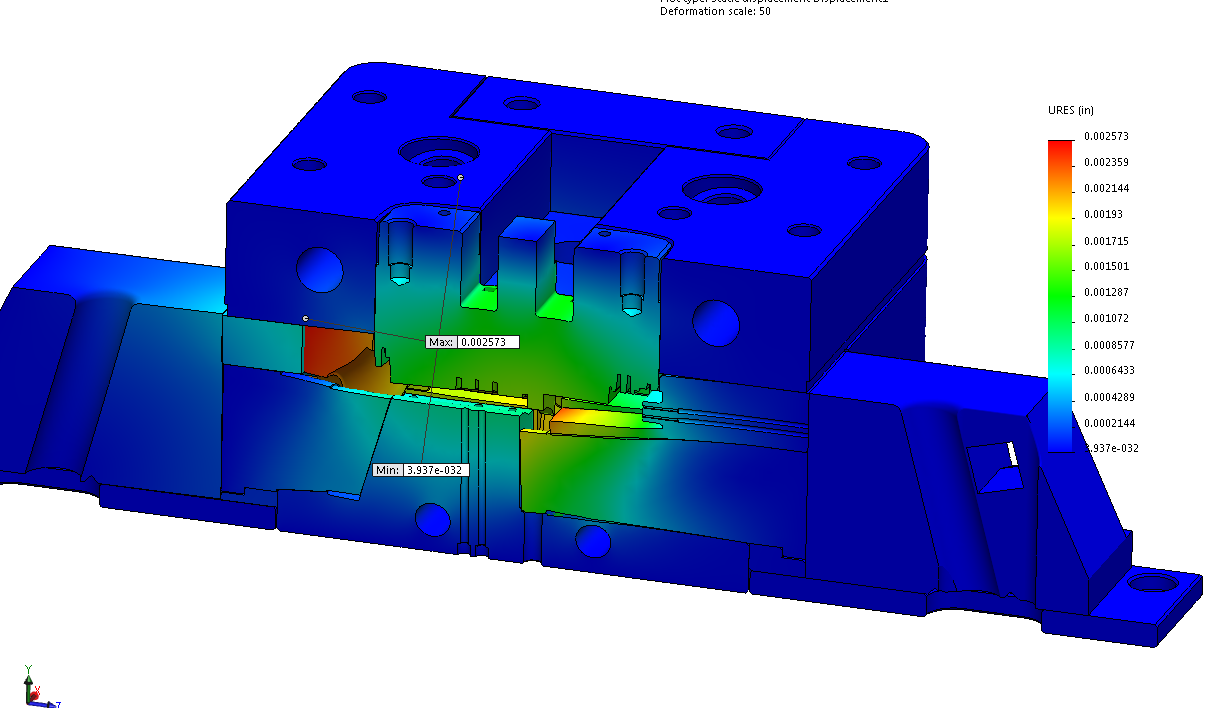

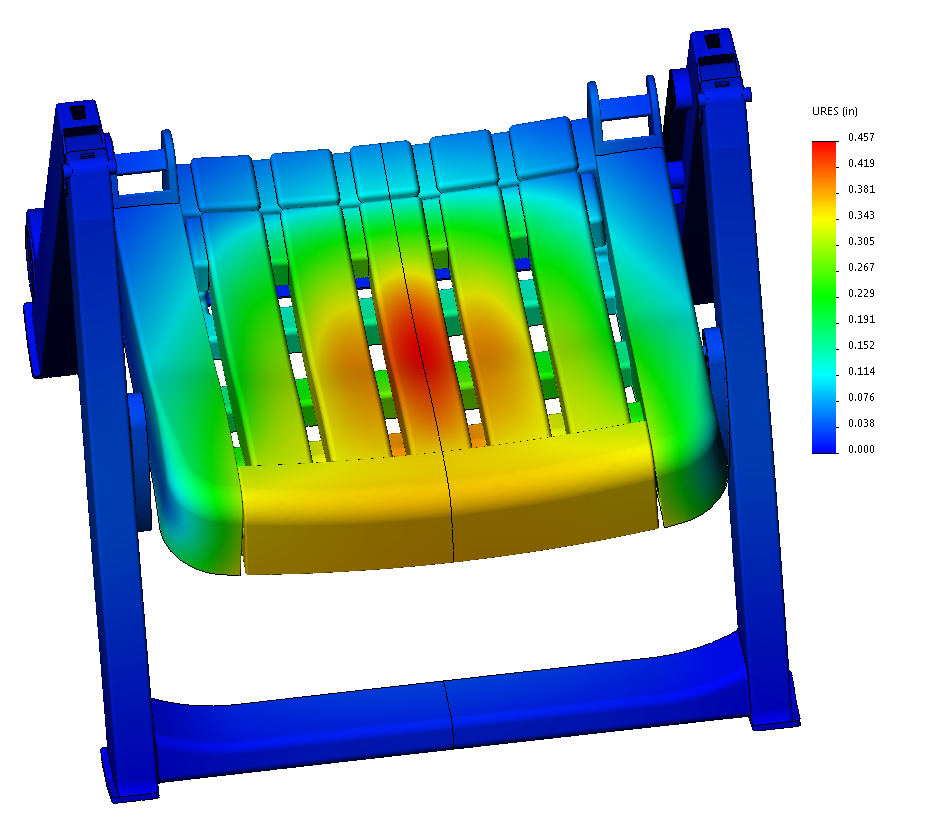

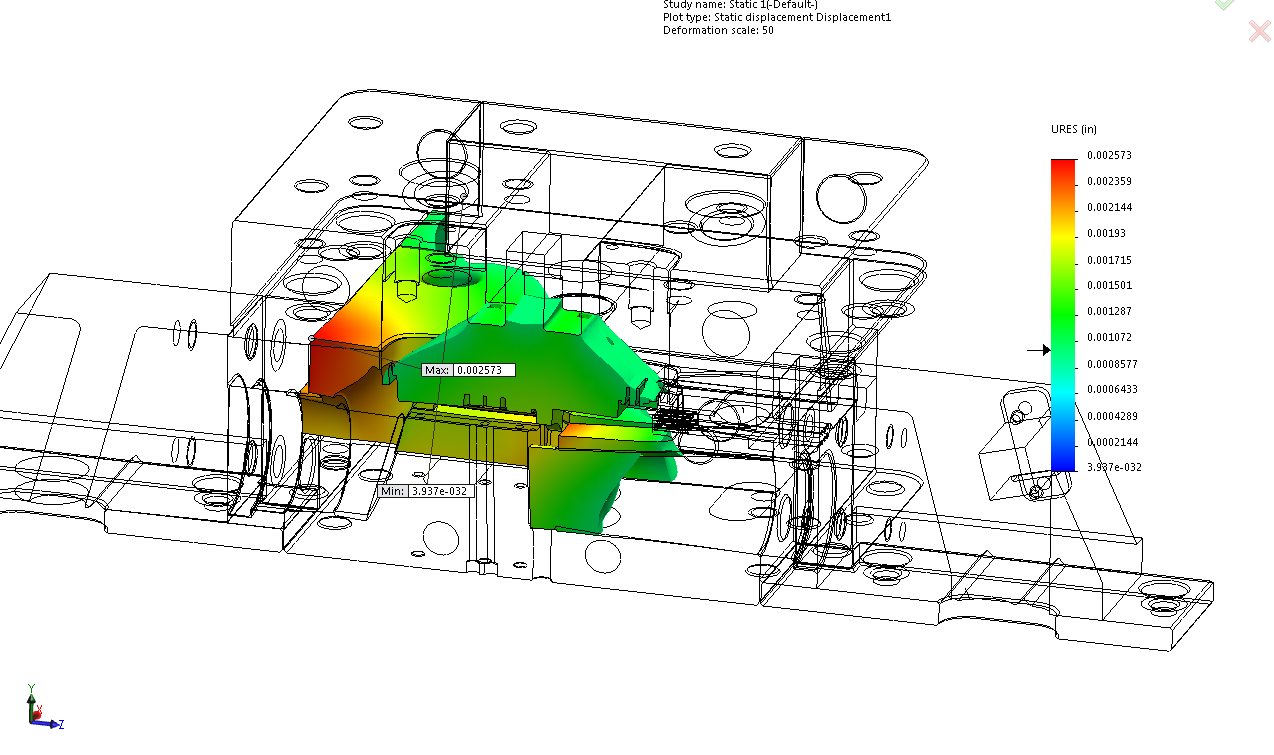

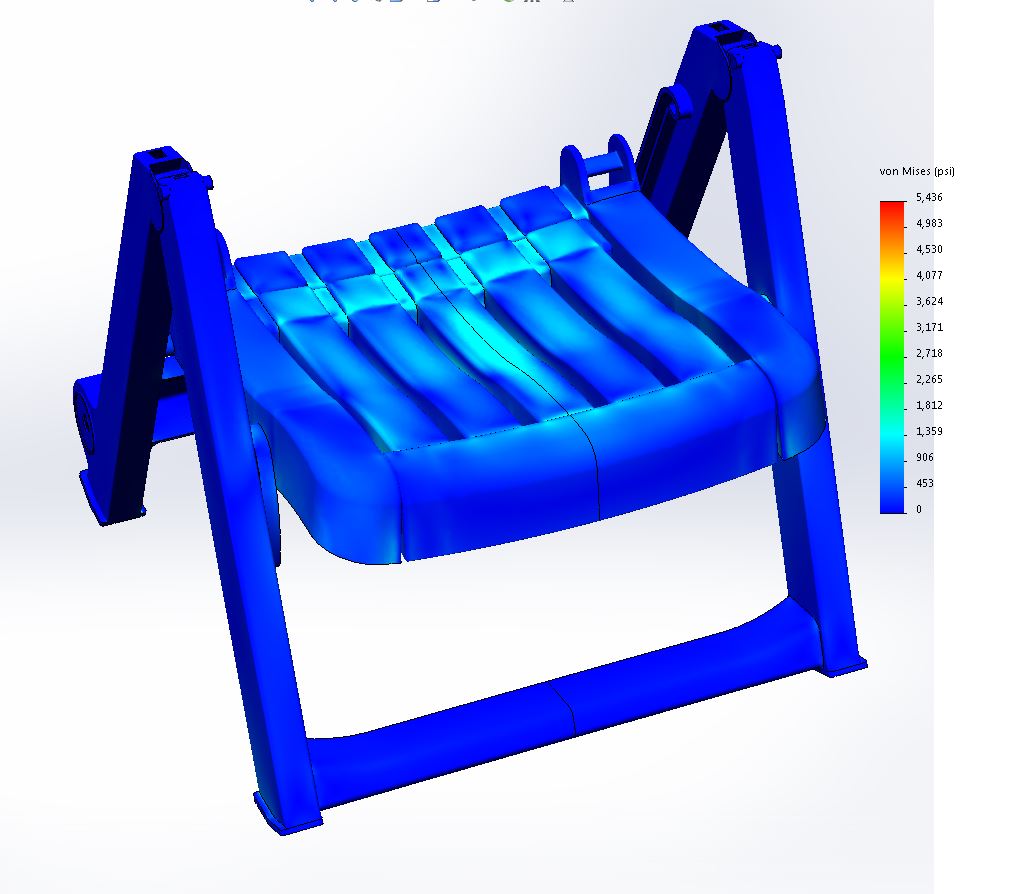

Product designs and mold designs that have any moving parts or loads applied go through elongation, bending, impact, and associated material stresses. These stresses can negatively affect the product’s performance if the stresses exceed what the material can withstand. Understanding these stresses and where they are located can give light to how to improve the design. These stress analysis evaluations may dictate that there is a Material Selection change or an Impact Analysis done to evaluate if the product can withstand a sudden drop. The software packages now can create many different colored plots and animations to show how the part is stressed as the load is applied. Product deflections can also be displayed at a 1 to 1 or even 100 to 1 ratios so that you can visualize how things are moving. This becomes very helpful in understanding the affects of the load and where things actually bend and / or break. Sometimes these analysis can be quite counter intuitive which makes them so valuable. Once the analysis is complete, the part or assembly can be cut and display the stresses internal to the wall section and also across the surface. The software also limits the stress plots to only display the stresses above or below a limited amount. This allows for easy display and understanding of all the areas that may be causing the problem and allow for improvement.

Procad Tchnologies, LLC

ALL RIGHTS RESERVED

Contact

352-600-7473

Spring Hill, FL